Create alternative budgets, define the WBS in detail and quantify your costs .

Simplify and detail every aspect of your project, including resources and tasks.

Optimize processes, increase productivity, solve critical issues, and ensure delivery times to your customers.

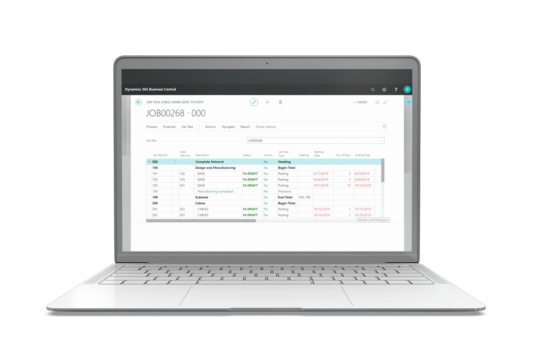

IEM, acronym of Industrial Equipment Manufacturing, is the software solution for Microsoft Dynamics 365 Business Central made for SME production by Job management.

IEM allows to optimize processes, increase productivity and solve typical SME Job management issues.

Through a complex and highly structured information system it is always possible to manage the status of the job at each stage.

IEM allows you to plan the job creation process according to customer specifications, manage work cycles and resources capable of generating custom products and coordinate complex procurement with great variability.

With IEM you can manage:

IEM is an international solution produced by To-Increase, distribuited and installed in Italy by Serenissima Informatica and its partners NAV-lab.

We chose IEM and To-Increase because they guarantee end-to-end solutions which are strongly verticalized on the processes and markets of reference, with almost total coverage of customer requests.

IEM is supported by a basic infrastructure that expands the already rich functional coverage of Microsoft Dynamics 365 Business Central and ensures flexibility and integration with external products.

Create alternative budgets, define the WBS in detail and quantify your costs .

Simplify and detail every aspect of your project, including resources and tasks.

Divide your work in the various phases of the WBS, Work Breakdown Structure: you have the possibility to define distinct bases and complex and specific work cycles for each individual job.

Store the current version of your technical data. You can always check the changes made by your technicians and keep track of the various modifications.

Schedule your work in function of your project timings.

Make sure that the material sourcing for a specific job takes place on time.

Manage the available resources on time as planned tasks change.

Get a complete overview of operators, machines and materials with an comprehensive breakdown for each project.

Ensure that there is no overlap or waste of resources.

Manage all incoming stocks and organize your deliveries based on jobs and locations to allow everyone to work more efficiently.

Know the materials needed for the jobs and make sure they are not used in other jobs with the job inventory feature.

This feature allows you to quantify with precision and in detail all your jobs.

"*" indicates required fields